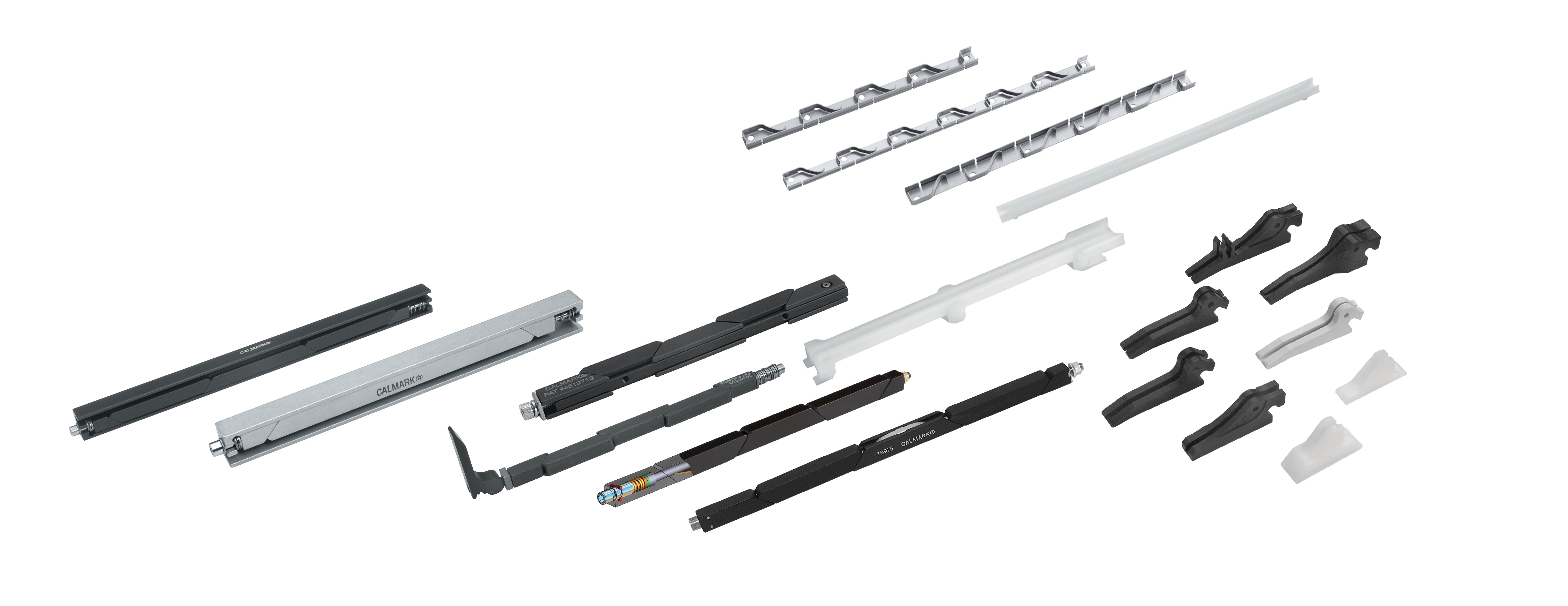

Mechanical Printed Circuit Board (PCB) hardware and retainers are an important component in any electronic subassembly or system, as they provide the required clamping force and placement to board module assemblies, electronic subracks or system chassis. Below are 5 things to consider when specifying this hardware:

Clamp Force – Consider the level of shock and vibration for your application. In industrial, avionics, or military applications, the electronic assemblies are often subjected to continuous vibration or high shock events. For applications where shock or vibration is a concern, Card and Wedge Loks are the preferred board retention method. High performance designs are available that provide 3X the clamp force than traditional Card or Wedge Loks.

Thermal performance – In addition to providing structural support and securing the printed circuit boards, retainers actively remove heat from the printed circuit boards, ensuring they do not overheat through conductive cooling. High performance designs also facilitate improved heat transfer.

2nd Level Maintenance – Will the PCB need to be replaced in the field? If so, there is torque limiting technology that enables field replacement of boards without specialized hardware or knowledge. Card Loks featuring torque limiting technology provide consistently repeatable and highly reliable clamp force and thermal performance without the need for specialized tools, ongoing calibration or technical knowledge.

Quality Requirements – What quality requirements will need to be followed? Consider vendors that can support DFARS, NADCAP, and other quality flow down requirements.

Customization – Are there any design modifications required? Common modifications include retainer length or number of wedges if it’s a Card or Wedge Lok, relocation of mounting holes, different material alloys, or replacement of split washers with Belleville washers. For a full list of common modifications, go here.

Click here to start configuring your printed circuit board retainer or download CAD files now!

For more details on printed circuit board selection, check out this white paper!